FÖRSTER welding tables have been proving their flexibility and durability for more than 30 years.

By combining the proven concept of the T-groove of machine tools, with the special grey cast iron rails as a surface, we manufacture a unique welding and assembly table – Made In Germany.

Fast dimensional and angular precision clamping as well as reduced idle times form the perfect basis for each of your future welding tasks.

Standard- Welding tables

robust - without grid constraints - Made in Germany

- Life-long protection against the build-up of welding spatters.

- Available in standard version stationary and mobile.

- With additional functions for lifting, turning, tilting and pivoting.

- Point loads up to 1.5 t – surface loads up to 3.0 t

- Surface flatness rail +/- 0.05 mm

- other variants on request

Modular design and robust surface

- The welding table can be extended and is ideal for assembly and welding work of all kinds, up to heavy steel construction.

- The rails of the welding table surface can be removed individually and thus allow size adjustment of the table surface by partial placements.

- The solid material forgives scratches, impacts and other damages – The welding spatter protection remains!

a small amount of accessories = maximum freedom

- With our in-house developed clamping system and stop elements you work precisely, with exact dimensions and angles WITHOUT grid constraints.

- Through the multifunctionality of our modules you have the opportunity to achieve a lot with a small amount of accessories, combine the available accessories and also use third-party tools.

Rotary welding tables

robust - without grid constraints - Made in Germany

- Welding table with 360° rotation function and easy handling

- Locking the table surface with manual parking brake

- adjustable without tools

- Point loads up to 1.5 t

- Surface loads up to 2.0 t

- Surface flatness rail +/- 0.05 mm

Lifting- welding tables

with electro-hydraulic scissor lift

Maximum flexibility is also provided by optional wheels for easy transport or the version with height-adjustable feet to compensate for uneven ground.

- stationary or mobile available

- Height adjustable up to 1250 mm

- Point loads up to 1.5 t

- Component weight up to 3.5 t

- Surface flatness rail +/- 0.05 mm

Lifting-rotary welding tables

with electrohydraulic scissor lift base and swivel ring

A combination of rotary and lifting table for maximum flexibility.

Height adjustment by means of hydraulic scissor lift, a manual rotation function of the table surface and an optional underrun frame offer maximum ergonomics during welding.

- stationary or mobile available

- Stroke up to 1250 mm height

- Point loads up to 1.5 t

- Component weight up to 2.0 t

- Surface flatness rail +/- 0.05 mm

Lift-tilt welding tables

for maximum ergonomics at the workplace

Thanks to the electro-hydraulic height adjustment and inclination setting, this welding table forms the basis for a flexible and ergonomic workplace.

- Stroke electrohydraulically from 550 mm – 1050 mm

- tilting electrohydraulic +/- 45°

- Point loads up to 1.5 t

- Component weight up to 2.0 t

- Surface flatness rail +/- 0.05 mm

Reversible welding table

Double-sided machining without forced positioning

FÖRSTER- Reversible welding tables are equipped with an electric motor-driven rotary actuator, which allows continuous 360° positioning of the table surface.

All models come standard with 12-rail partial coverage to provide all-sided access to the weld seam.

- For workpieces up to 3000 mm length

- 360° rotation function

- Point loads up to 1.5 t

- Surface loads up to 1.5 t

- Surface flatness rail +/- 0.05 mm

Table bridges

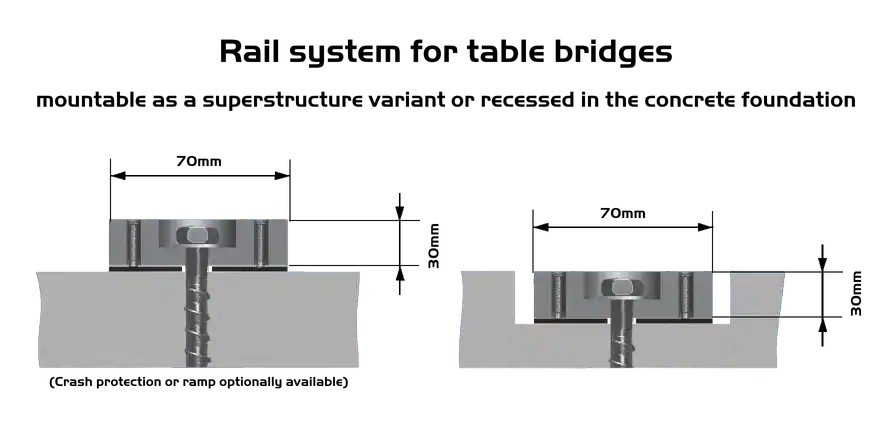

Our variable floor rail system for mobile table bridges is highly resilient and can be used universally.

Table bridges are the perfect solution for the production of variable length welded structures.

The table bridges can be moved on a rail system by self-lifting and can be fixed securely in a 100 mm pitch.

Due to the portability of the table bridges, the working area can also be variably designed or completely cleaned.

Our rail system is designed for mounting in or on concrete and can be executed in any length and width.

- Point loads up to 1.5 t

- Area load up to 5 t per bridge

- Feet with spring-loaded and guided rollers

- Can be fixed securely

welding fume extraction

Effective extraction of welding gases

The extraction of welding fumes is always a complex challenge. A constant carrying of a suction hose on the weld is often not accepted by the user as it is required.

FÖRSTER- Welding tables with integrated smoke extraction allow continuous welding smoke detection through the table surface. Variably, areas of the table surface can be connected to the exhaust air flow.

FAQ

frequently asked questions

FAQ

FÖRSTER welding tables are characterized by their durability.

Even under the harshest conditions, our special grey cast iron table surface retains its weld-spatter-repellent properties for many years. The older a FÖRSTER welding table becomes, the less maintenance is required.

This means no loss of properties = permanent protection against welding spatter.

FÖRSTER welding tables are robust and torsion-resistant assembly and welding tables on which you can assemble, hammer, grind and of course weld.

…more on this can be found under Technologies.

With a FÖRSTER welding table, the rails of the table surface can be removed individually and thus open the table surface. This way, components can be inserted into minus z and laid out flat at the same time without costly extensions.

Thus, a FÖRSTER welding table offers you maximum flexibility and an actual work in 3 dimensions, including “minus Z”.

Find out more under Technologies or experience our input animation.

When tensioning, focus on the component and not on the hole grid of the table.

Simply place your assembly on the table and bring your stop, clamping and support elements in position steplessly as your component specifies.

Due to the continuous movement of the keystone and the range adjustment of the clamping Elements you can reach every point on the table.

And thanks to our rhombus nuts, you can also use clamping and stop elements in already assembled grooves… Find out more under Technologies.

Our range of accessories is well thought out, universally applicable, easy to grasp and intuitive to understand.

FÖRSTER clamping and stop elements are designed to be used in various functions and can be easily combined with other clamping and stopping devices.

The range includes a little more than 30 parts with which you can cover almost any welding task. FÖRSTER offers you a compact modular system of clamping devices and stop elements that can be combined with each respectively are interchangeable with each other.

In addition, our groove system offers the advantage that you can use self-made stop elements (for example special moulds) on our table.

You can simply continue to use existing accessories for perforation systems, thanks to our adapters.

Our welding tables are manufactured and assembled at our HQ in Hohenstein-Ernstthal.

We cut the surface, CNC machine, finishing and assembly everything in-house. The same applies to the table base, which is welded and painted in our house.

Accordingly, we can implement customer wishes individually.

Made in Germany