Welding automation from a single source!

We design, construct and manufacture your very special robot welding system completely in-house.

We accompany you from the idea to production maturity and beyond.

Our all-round carefree package includes:

Plant concept – engineering – production and assembly – commissioning – technology optimization – service

With our long-standing know-how, we meet your challenges and develop the ideal solution for you.

welding automation

An ideal solution for the realization of your task cannot be taken off the shelf. Benefit from our many years of experience with all welding processes.

Each welding assembly has specific properties during machining, requires adapted fixtures and can ideally be produced even more efficiently. We evaluate the optimal welding process for your welding task, select the appropriate welding equipment manufacturer and an optimal process parameterization.

In our considerations for the realization of your requirements, besides the factors quality and quantity, also the aspects ergonomics, flexibility and easy operation play an essential role.

Every system must offer added value and be enjoyable to use.

welding technology

We develop solutions for efficient component production based on the customer and component-specific requirements, already within the concept phase.

With customer components, sample welding can be carried out on a ready-made robot system in order to define the ideal welding process in advance. As an independent system house, we can rely on numerous welding equipment manufacturers and also the cooperation with colleges and universities helps us to integrate new and innovative solutions for your project.

Our technologists, automators, designers and fixture manufacturers work together to develop a comprehensive solution for the automated production of a perfect welding assembly.

fixture design

Our over 30 years of experience in the construction of welding equipment forms the basis for designing the core of a customized welding robot system, the welding device, with the highest quality.

Central points are the exact positioning and tensioning of the individual parts, the general accessibility to all welding seams, the protection of the device against welding spatters as well as a counteraction of the resulting weld distortion as well as the comfort during operation.

Nothing is more important than producing quality efficiently!

process stability

According to our experience, it is much more advantageous to use a high-quality device for a weld assembly than having to perform corrections with electronic systems.

However, these electronic systems can play their added value for the detection of variable welds or in response to changing circumstances.

In addition to classic seam tracking, we can also integrate laser scanning systems, camera systems or simple optical sensors into your welding robot system.

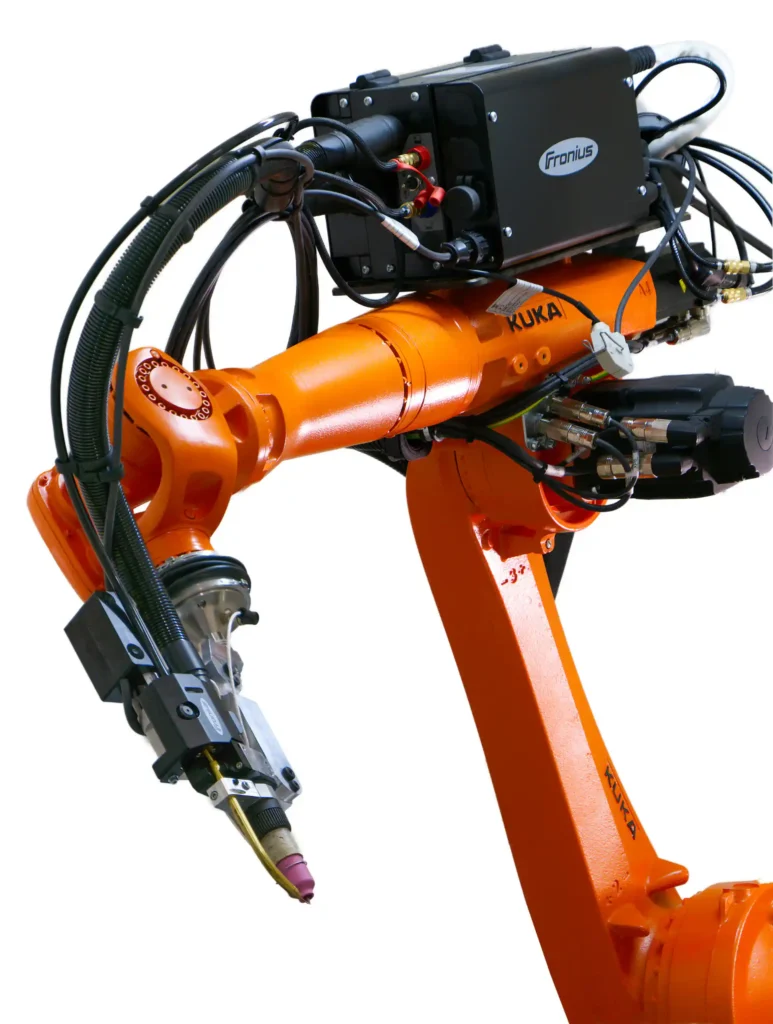

robot technology

We rely primarily on robot technology from the brands Fanuc and KUKA.

In addition to range simulations and load calculations, realistic considerations of necessary reserves are also taken into account when selecting suitable robot types. What works on paper can fail in reality.

By combining several welding robots, handling robots or grinding robots, turning and moving axes, as well as the integration of other technology systems, we significantly increase the degree of automation and thus your productivity.

control and programming

Every new robot plant brings with it, in addition to the challenges of mechanical design, new tasks in the field of software development.

Due to our in-depth knowledge of the existing possibilities as well as the limits of the robot systems we use, we are able to create a software concept and implement it in the shortest possible time.

Our automators not only consider the control programming of the pure welding task but also possible requirements of, for example, data retention or order management systems.

We have the know-how 4.0.

Thanks to our experience in classical custom machine construction and its control algorithms, we can create a digital system that meets the requirements of “Industry 4.0”.

We use logic controllers from Siemens or Beckhoff, depending on the requirements, to control supporting systems such as marking stations, handling portals or for data management.

training and support

With the production of a welding robot system and completed technological commissioning, our task is not yet fulfilled.

Our aim is to teach you how to handle your product. Starting with the first steps to control a robot, we will train you in depth so that you can create your own robot programs.

During the start-up phase, we are of course at your disposal with telephone support, use remote maintenance systems or come to you.

Your independence in the operation of your robot welding system is our goal.