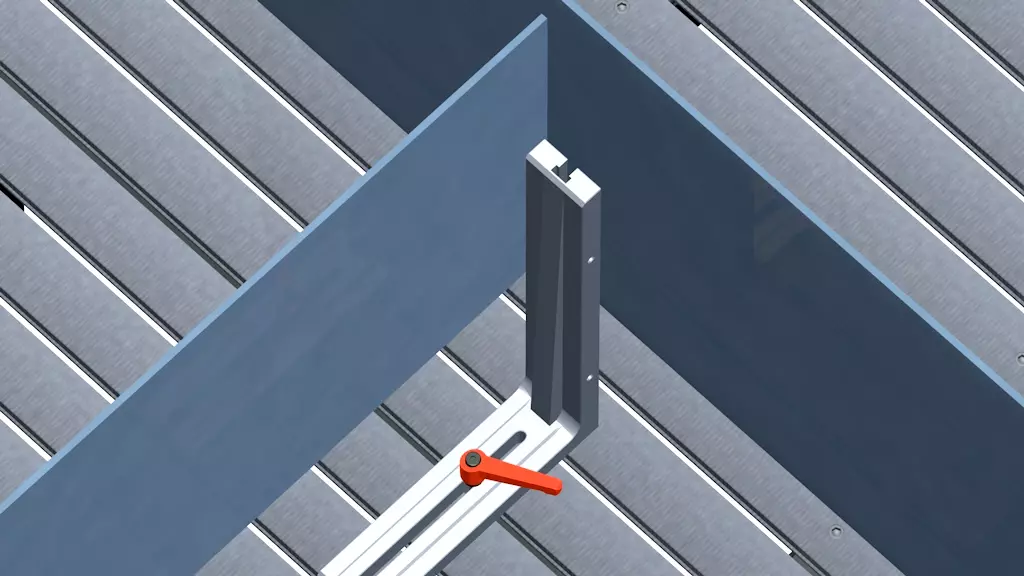

Infinitely variable and secure positioning without grid constraints thanks to the integrated T-slot clamping system.

Surface materials with consistent properties over a period of many years, even in rough use

A modular system that stands out for the variability and versatility of its products

Three building blocks, connected from an ergonomic point of view.

Highest quality, made in Germany!

T-slot system

continuously variable positioning without grid constraint

- With our T-groove system, all clamping elements and stops reach any point of the table.

- Precise clamping by continuously moving the stop and clamping elements.

- Weld and mount frames, pipes, housings and more in any position you want.

- Easy positioning by moving to the desired position.

- Each slot stone can accommodate several elements, depending on the accessory.

- Additional clamping means and stop elements can be inserted at any time without having to re-clamp.

- Compared to borehole systems, the T-Slot system always offers sufficient support points.

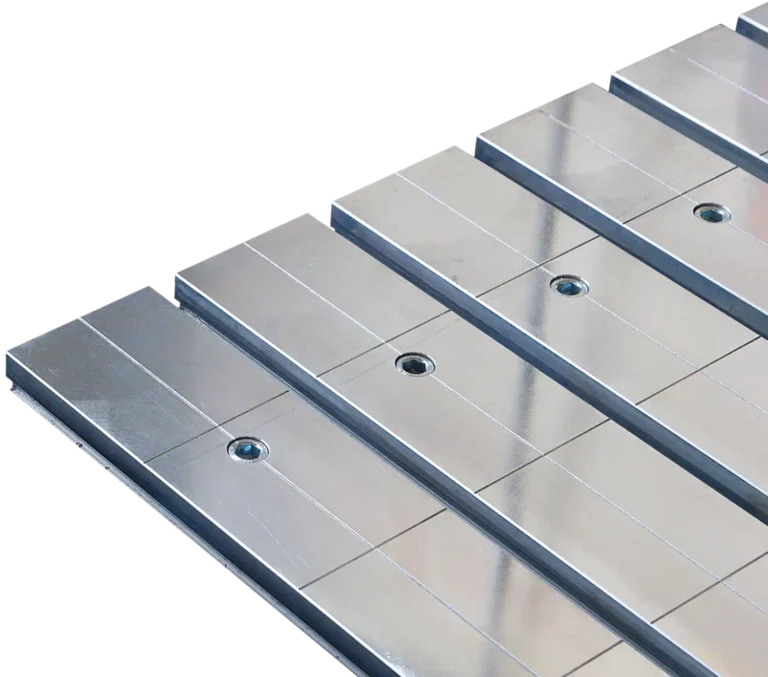

special gray cast iron

Special grey cast iron rails for steel and aluminium processing

The open-pore milled surface allows release agents to penetrate easily into the coarse structures. In combination with graphite, this creates the perfect welding spatter protection!

The evaporation of the separating oil when a weld spatter hits the surface creates a gas bubble and causes the immediately cooling weld spatter to run off.

Advantages:

The older the table, the less maintenance is needed to maintain its properties:

- Grey cast iron ages and with this ageing graphite parts diffuse to the surface, which is expressed in an increasingly gray color and thus provides a basic protection against welding spray adhesions.

- By using solid material instead of just a coating, our rails retain their properties for a lifetime.

- The lower elongation coefficient of cast iron compared to steel minimizes warping under heat influence during welding.

- The surface of solid material is highly resilient – wear, scratches, impacts etc. do not affect the properties.

aluminium-copper alloy

Non-ferritic rails in Al/Cu alloy for stainless steel processing

- Rails made of solid material with life-long properties

- enables the consistent separation of ferritic and non-ferritic materials to avoid ferritic scratches in stainless steel welding.

- Extremely high thermal conductivity against steel to minimize distortion

- almost complete avoidance of adherent welding spatter

- Customized, universal accessories for stainless steel processing available

- max point load single rail: 1.0 t

modular system

Interchangeable or combinable accessories and extensions

Vorteile:

Nowadays, the pure welding time can hardly be reduced by modern manufacturing processes. The majority of the working time is required for the exact arrangement of the individual parts, as well as measuring, straightening and correcting.

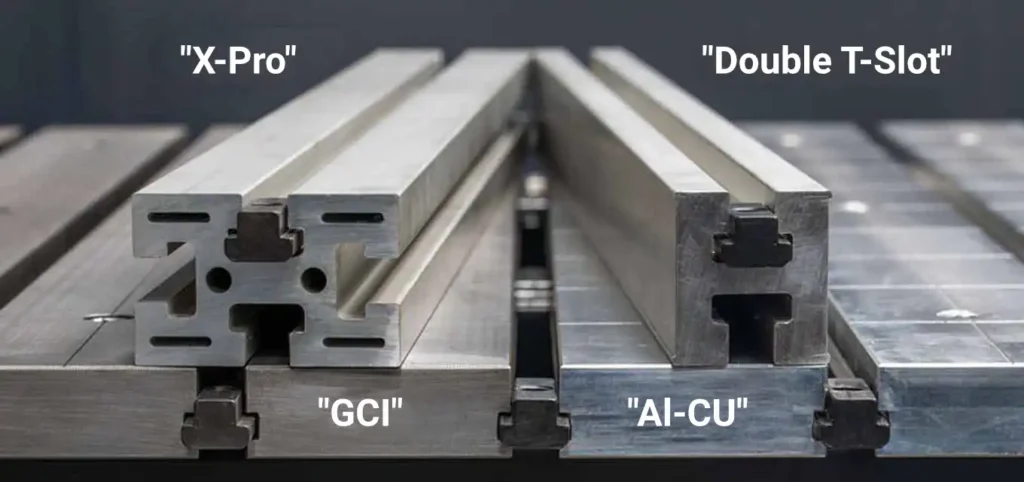

Our modular system consists of:

- Grey cast iron rails with T-groove

- Al/Cu rails with T-groove

- X-Pro profiles with T-groove

- Double groove profiles with T-groove

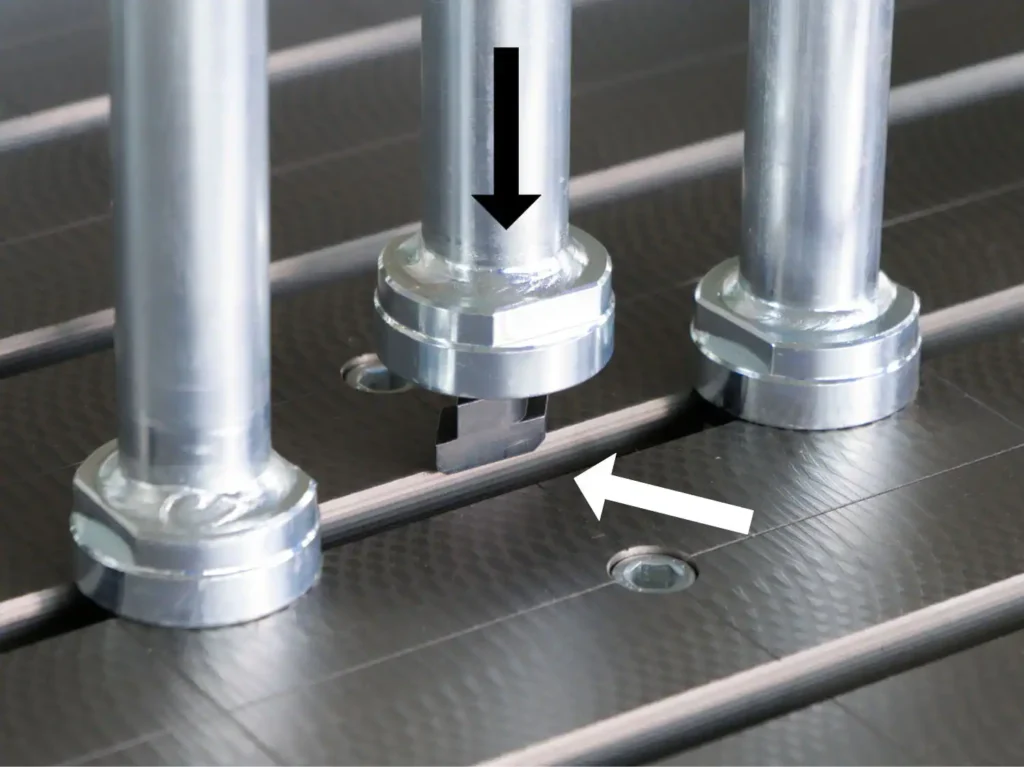

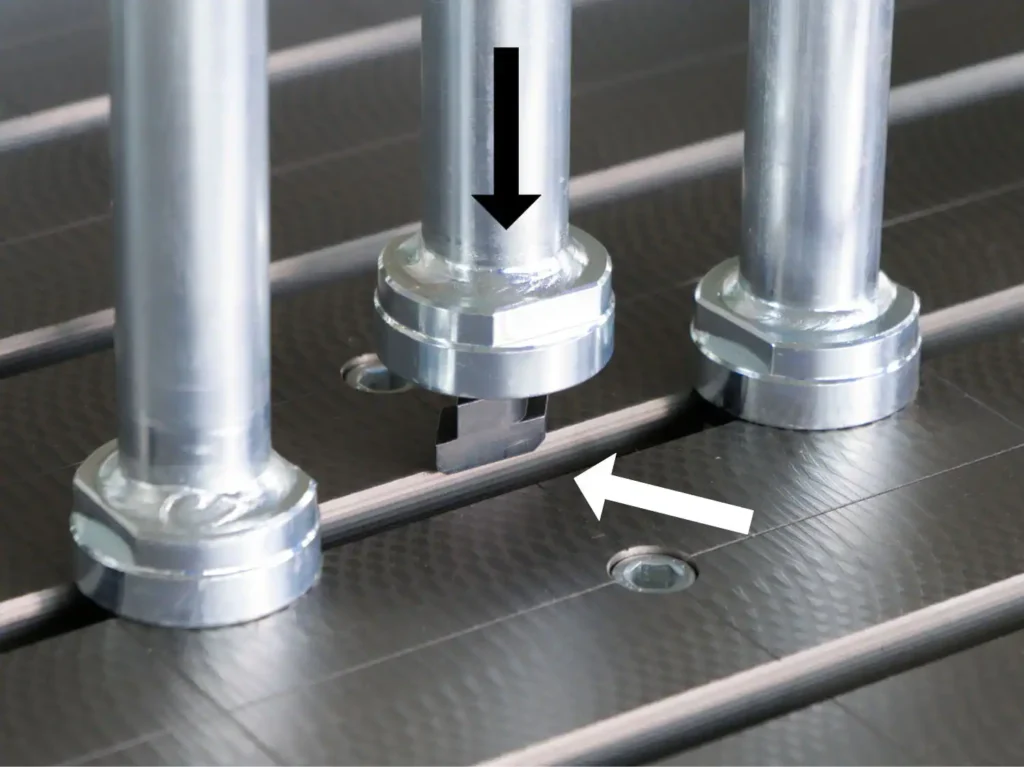

- Stop and clamping elements with slot stone

- The accessories range consists of just over 30 parts with which you can cover almost any welding task.

- Stop element can be used universally or on both sides – that means: no right or left versions of individual accessories.

- Clamping in height and width are possible with any length and angle. Profiles are delivered as meter goods and can be freely assembled and combined

Detailed description of the properties of all tensioning and stop elements can be found at “accessory“.

FAQ

FAQ

The advantages of a T-Slot system are obvious.

- Since our accessories are generally equipped with range regulation, you can reach every point on the table.

- The T-Slot does not become dirty. In contrast to perforated systems where the system holes quickly become dirty, which makes it increasingly difficult to insert and remove accessories, the T-groove remains free of dirt. Stop and clamping elements can be easily guided through the grooves even after years of use.

- The T-Slot system has the advantage that you can use self-made stop elements (for example special shapes) on our table.

Yes! The durability of a coating depends on the type of coating and in particular on the thickness of the coating. But no matter how good a coating may be, it is not permanent. Depending on use, even high-quality coatings can be removed after just a few months. That means, the advertised properties are then no longer given.

Our table top made of solid material retains its properties for a lifetime. This means that you can simply get started on a FÖRSTER welding table without having to take special care or consideration for the surface.

The biggest advantage of our modular system is the intercompatibility of the individual parts. This means that you can combine, exchange or modify notches, stop elements and clamping devices according to your own needs. Our range of accessories is not a closed system that binds you to us, on the contrary: You can equip yourself according to your needs with additional tools and use them on our table.

For tools and clamping devices for borehole systems we offer adapters so that you can continue to use them.

Our welding tables are manufactured and assembled at our site in Hohenstein-Ernstthal.

We also cut the surface in-house, CNC machining, finishing and assembly. The same applies to the table base, which is welded and painted in house.

Accordingly, we can implement customer wishes individually.

Made in Germany